OPERATIONS RESEARCH APPROACH IN THE METHOD OF ANALYSIS AND PROBLEM SOLVING (MASP)

THAIS SILVÉRIO SALVADORI1 - MISCHEL CARMEN N. BELDERRAIN2

Instituto Tecnológico de Aeronáutica – ITA. São José dos Campos, Brasil

thaissilvasilverio@yahoo.com.br - carmen@ita.br

Fecha recepción: diciembre 2021 Fecha aprobación: abril 2022

ARK CAICYT: http://id.caicyt.gov.ar/ark:/s18539777/p5zjm9klv

ABSTRACT

Currently, with fierce competition in the job market, companies are seeking continuous improvement of their services, seeking to increasingly expand their clientele. In this sense, organizations are increasingly committed to reducing losses and rework. However, problem identification, analysis and solution is a very complex process, in which you need a multidisciplinary team and an efficient process for an effective solution. Thus, the objective of this study is to add to the method of analysis and problem solving (MASP) a structuring step and to use a multicriteria method for prioritizing actions. So, the proposed method uses: (a) MASP method (Problem Analysis and Solution Method) and its respective quality tools with a focus on problem analysis and solution and; (b) the PFM (Problem Focused Method) method with a view to a robust structuring of the problematic situation and, c) the AHP (Analytic Hierarchy Process) method for prioritizing actions. The proposed method was applied in a manufacturing unit during the validation of the implementation of a new process. At the beginning of production there was a high level of rejection of batches and losses in the production process, with the resolution of the problem a rate of less than 1.00% of rejection of batches in the production process was achieved.

KEYWORDS: MASP (Problem Analysis and Solution Method), PFM (Problem Focused Method), problem structuring, multidisciplinary team.

RESUMEN

Actualmente, con una feroz competencia en el mercado laboral, las empresas buscan la mejora contínua de sus servicios, buscando ampliar cada vez más su clientela. En este sentido, las organizaciones apuestan cada vez más por reducir pérdidas y retrabajos. Sin embargo, la identificación, análisis y solución de problemas es un proceso muy complejo, en el que se necesita un equipo multidisciplinar y un proceso eficiente para una solución eficaz. Así, el objetivo de este estudio es añadir al método de análisis y resolución de problemas (MASP) una etapa de estructuración do problema y utilizar un método multicriterio para la priorización de acciones. El método propuesto utiliza: (a) el método MASP (Método de Análisis y Solución de Problemas) y sus respectivas herramientas de calidad con enfoque en el análisis y solución de problemas y; (b) el método PFM (Problem Focused Method) con miras a una estructuración robusta de la situación problemática y, c) el método AHP (Analytic Hierarchy Process) para priorizar acciones. El método propuesto se aplicó en una unidad de manufactura durante la validación de la implementación de un nuevo proceso. Al inicio de la producción se presentó un alto nivel de rechazo de lotes y pérdidas en el proceso productivo, con la resolución del problema se logró una tasa de rechazo de lotes menor al 1.00% en el proceso productivo.

PALABRAS CLAVE: MASP (Método de Análisis y Solución de Problemas), PFM (Método Focalizado en Problemas), estructuración de problemas, equipo multidisciplinario.

1. INTRODUCTION

World-class companies differ from traditional companies in the way they manage their resources to optimize their competitiveness. The market is always passing through transformations that demand dynamism from organizations looking for quick solutions to problems that are common in operational and management processes. Competitiveness for prices and quality has become increasingly sharp, mainly in countries that have high technology or more expensive manufacturing costs. (Salgado et al 2009).

Seeking the need for customer satisfaction, organizations look for improvements in their methods and processes, aiming at the excellence of their products and services, including in the health sector. So, organizations need to identify and mitigate the factors that cause waste (time, unnecessary activities, rework, etc.) of the processes to reduce the lead time and costs, bringing a competitive advantage to the organization to face other competitors (Salgado et al 2009).

The non-conformity analysis is an inherent process at organizations, especially in companies that have strict environments of quality control, such as the high-volume industries. According to Campagnaro (2007) any process is subject to the occurrence of non-conformities, daily. This fact is due to the high complexity of the processes involved, in addition to innumerable variables that can cause a failure, being practically impossible to have control of all of them. Thus, as we have an environment in which the probability of occurrence of a non-conformity is high, it is necessary to use methodologies to address these problems, such as the probable causes evaluation and corrective actions to reduce the recurrence of causes, to guarantee the quality of the products (Hagemeyer; Gershenson, Johnson 2006). However, problem solving, if not carried out with well-defined planning and aligned with stakeholders’ goals, can, in most cases, bring actions that require a lot of investment (related to cost) and a long term of implementation (related to time).

One of the most used ways in the industry for the treatment of non-conformities is the Method of Analysis and Solution of Problems (MASP). However, the application of the MASP method is directly linked to several human, technological and organizational factors. Aguiar (2004) mentions, for example, imprecision, inadequate training and lack of tools as some characteristics that lead to failures in the application of MASP. Thus, the objective of this study is to improve the method of analysis and problem solving (MASP) by addition of a structuring step and the use of a multicriteria method for prioritizing actions.

2. LITERATURE REVIEW

2.1. Problem Analysis Method (MASP) or QC-Story

In Brazil, the introduction of QC-Story was carried out by Vicente Falconi Campos who published an appendix describing the method in his book “TQC Total Quality Control in Japanese style”, in 1992 (Henriques, 2013; Versiani; Oribe; Rezende , 2013).

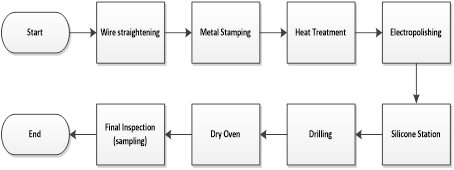

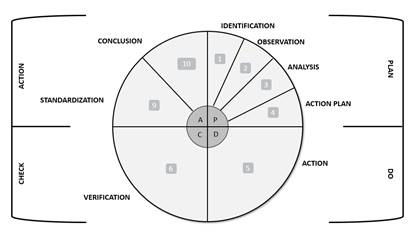

The process to be followed in MASP is based on the Plan-Do-Check-Act (PDCA) cycle, considering that each MASP stage is framed in the stages of the PDCA cycle. Severo, Melo and Medeiros (2004) explain that the method of analysis and problem solving makes use of the PDCA cycle, the only difference is instead using four steps, the MASP is subdivided into eight steps. According to Campos (2004), the method is a congruent series that aims to meet a certain objective, while tools are contributions to make the method effective, as FIGURE 1.

FIGURE 1. MASP cycle. Adapting from Campos (2004).

2.2. PFM

Problem Structuring Methods (PSM) methods are used where the problem is not in a structured way that means, the elements involved are not clearly identified. According to Mingers and Rosenhead (2004), a complex problem is characterized by the existence of several factors such as: multiple actors, multiple perspectives, conflicting interests, important intangibles, and key uncertainties.

The Problem-Focused Method is derived from several common concepts from PSM, in addition to other theories related to the in-depth study of the problem and decision-making processes. PFM originated with the objective of becoming an aid tool in the initial stages of identifying and structuring a problematic situation, in order to support a clear structuring of the problem based on interviews with those involved and investigations of the variations in the context (Cardoso Junior, 2019).

The maps are constructed from interviews with individuals, and in the end they will be brought together, providing a systemic view of the scenario to be studied (Eden, 2004). Each fact or statement reported by the interviewee is recorded in a box, then the facilitator writes a contrast to this sentence. As in the SODA (Strategic Options Development and Analysis) method, the box is called “construct”, which represent the client's informal knowledge and a contrasting point is given in order to minimize any ambiguity that may exist (Eden, Ackermann, Cropper, 1992.)

Based on the principles described, the problem maps use the concept of bipolarity in order to minimize the ambiguities existing in the interpretative process with the use of words or phrases that aim to reinforce the original description given (Georgiou, 2011). On the positive pole, there is the information provided by the stakeholder. They are separated from the negative pole by three points ("..."), which is intended to minimize the different connotations that the assertions by the client may assume, in order to improve the situational context and maximize understanding.

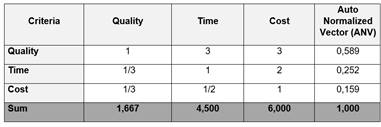

2.3. AHP

The Multicriteria method Analytic Hierarchy Process - AHP - emerged in the late 1960s and was developed by the mathematician Thomas L. Saaty, while working for the US State Department's Arms Control and Disarmament Agency.

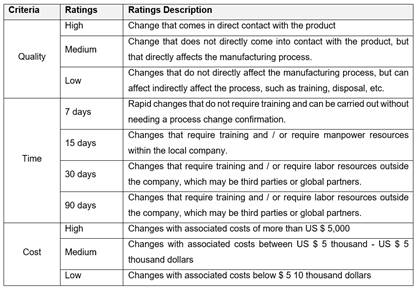

The Analytic Hierarchy Process (AHP) is a method used to assist in problem solving, especially when there are several criteria involved in the assessment. The method allows breaking the complexity of unstructured situations into simpler elements. AHP can be used to classify the importance of the relevant criteria in a decision. (Saaty, 2008). In the AHP method, there are two aspects to obtain priorities, the first is the comparison of an alternative with multiple existing ones (relative measure), while the second, each alternative is compared with the ideal alternative (absolute measure), through a process known as classification of alternatives or Ratings.

Ratings can be defined as a set of categories (or levels) that assess the performance of alternatives, considering each criterion and / or sub-criterion. It is important to emphasize that the categories should be classified in order to minimize the ambiguity between the criteria / sub-criteria, so that decision makers can distinguish the criteria / sub-criteria for evaluating the alternatives. (Duarte Junior, 2005).

According to Saaty (2008), the best way to work with ratings is by idealizing the priority vectors, in other words, the classification “excellent” receives classification 1 and the subsequent ones receive lower values. The intensity categories are then prioritized using the pairwise comparison and the alternatives are evaluated by selecting the designated intensity category for each criterion.

One of the main advantages of using Ratings is the decrease in the number of comparisons when there are a large number of alternatives. In addition, the use of absolute measures (evaluations), does not interfere if there is an addition or removal of alternatives, as there is no rank inversion in their classification Silva, Belderrain, Pantoja (2010).

3. RESEARCH METHOD

3.1. Description of the proposed method

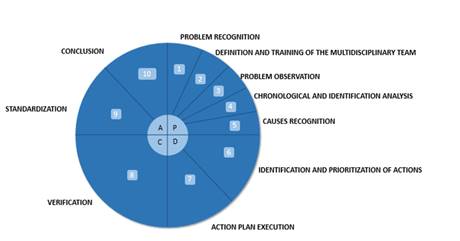

FIGURE 2. Proposed MASP method. Source: Author.

· Step 1: Problem Recognition: This step shows the process flowchart for a better understanding of the problem to be analyzed. Subsequently, the problematic situation is recognized, which is evidenced by the defect rate indicator per lot.

· Step 2: Definition and training of the multidisciplinary team, the multidisciplinary team that works to solve the problem and train all individuals in the tools applicable to the proposed method is defined, mainly in the MASP, PFM and AHP tools.

· Step 3: Problem Observation: This step consists of stratifying the problematic situation in the first step, in order to identify which defects are being found that affect the quality of the product and using quality tools to determine which defect will be solved using the proposed method.

· Step 4: Chronological and identification analysis: It is the most complex step of the method because it is the main step of analyzing problem solutions, the cause analysis. Firstly, for the analysis of causes, they are carried out using the problem maps using PFM method, where it was divided into 3 stages: Interviews and Constructions of the individual Maps, Construction of the Aggregated and Congregated Map and Qualitative and Quantitative Analysis of the Congregated Map.

· Step 5: Causes Recognition: The causes identified in the PFM stage are placed for a better visualization of the causes through the Ishikawa Diagram, and a group vote on the main causes that need to be analyzed.

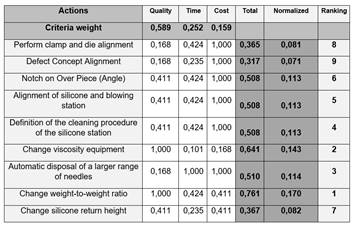

· Step 6: Identification and Prioritization of Actions: Generate the necessary corrective actions with deadlines and those responsible for execution. These actions are prioritized using the AHP Method.

· Step 7: Action Plan Execution: The actions, already prioritized, are implemented and the deadlines and those responsible are defined for the execution.

· Step 8: Verification: The action plan is now executed, with subsequent verification of its effectiveness through the analysis of the results obtained.

· Step 9: Standardization: Communication changes of the standards in a systematic way with details of each stage, locations and stakeholders can be carried out through an official document or channels.

· Step 10: Conclusion: Completion of the work and recognition of those involved.

3.2. Application of the proposed method

3.2.1. Step 1: Problem Recognition

The Problem Recognition and the understanding of the problem to be analyzed is facilitated by the process flowchart in FIGURE 4. In this application, the problem occurs within a medical device company, but specifically with surgical needles. The surgical needle is designed to take the surgical thread, penetrating it through tissues.

FIGURE 3. Process Flowchart. Source: Author

These materials would not go through the Final Inspection process, so it was decided to do the same sampling as the Final Inspection right after the drilled needles process in order to know the process robustness through the defect rate indicator.

The release of the products of the products at the Final Inspection is carried out using the technique of sampling inspection, thus having acceptable levels of quality for the batch. Thus, the same sampling that is current applied in the Final Inspection stage was replicated for the process.

FIGURE 4. Process Flowchart. Source: Author

Thus, the problem of a high number of defects was detected in this phase, it was demonstrated that process need improvements to ensure quality required by internal and external customers, which consisted of finding no defects at this stage of the process. Therefore, the Quality Sector reacted to this demand and developed strategies on how to solve the problem for the coming months, as well as a definition of better collection of defective data.

3.2.2. Step 2: Definition and Training of the Multidisciplinary Team

A multidisciplinary group, formed by specialists from different areas, was created to analyze and find the possible causes of the problem. Thus, the multifunctional group had the involvement of the following areas:

· Process Engineering - 1 representative

· Quality Engineering - 1 representative (facilitator)

· Development Engineering - 1 representative

· Production - 1 representative

These people were designated by the management, as they participated in the transfer of technology to the website, as well as in the development of processes and validations. The group leader, a member of Quality Engineering, was responsible for preparing and managing the discussions, as well as for stratifying the data to share the problem with the group.

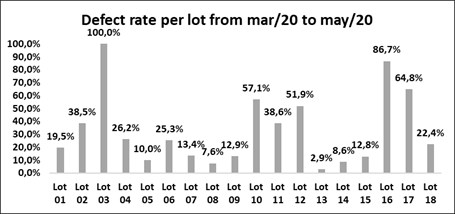

3.2.3. Step 3: Problem Observation

The observation of the problem occurred in order to stratify which were the Class I defects. Previously, the collection of information on inspection defects happened informally, in which the main information obtained was the defect rate. From these lots, an inspection checklist was created in order to identify, quantify and classify the defects found, according to applicable rules.

In order to obtain this information for the analyzed lots, a resampling was carried out to obtain these stratified data. The checklist presents the product code, lot number, tray number, defects (quantity, code, classification), operator, and date. The standardized classifications help to find the region, or the form of the problem contained in the product, as well as the classification of the defect.

Thus, with the means of identification established, it was possible to stratify the sampled lots, the sum of the defects for each batch is above acceptable levels, so the batches would fail. In addition, it was found that most of the defects found are Class I, that is, a defect in which it may imply a serious injury to the client, the lowest rate found for Class I was 2.9%.

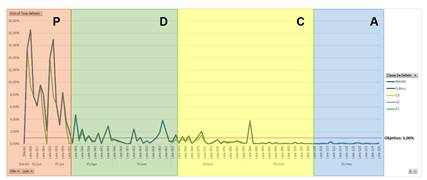

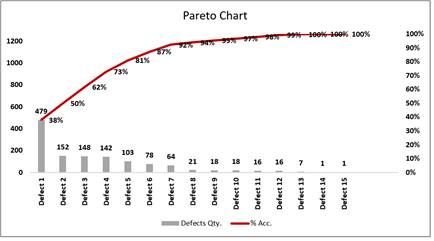

Data stratification continued through the Pareto Graph to find out which defect was most frequently negatively impacting the product, as shown in FIGURE 5.

FIGURE 5. Pareto diagram for defects. Source: Author

As can be seen, 80% of the defects are defects 1,2,3,4 and 5. The study in question focuses only on Defect 1, as the other defects had the causes and actions already underway by the team, for example. if it is a problem of simple resolution, then only Defect 1, called Incorrect Silicone, was addressed. The remaining defects were not explained to preserve the company's image.

3.2.4. Step 4 - Chronological and Identification Analysis

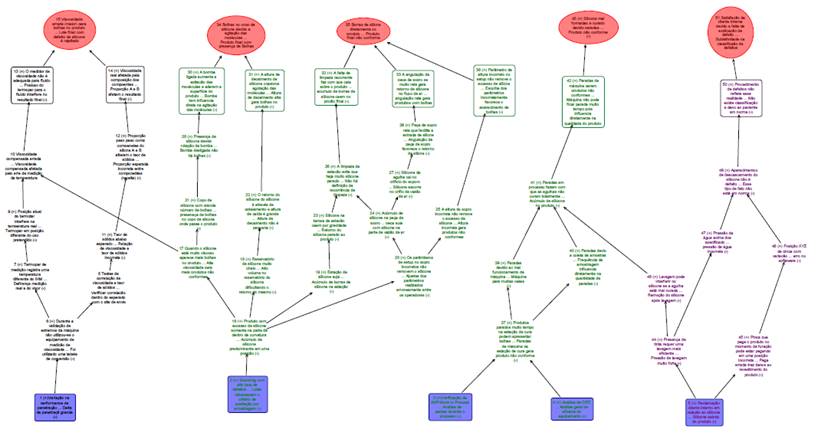

3.2.4.1. Step 4.1: Interviews and Construction of Individual Maps

The objective of the interviews with the multidisciplinary team was to understand each stage of the process and the difficulties that exist in them. In addition, the focus of individual interviews was so that there was no loss of information and did not discard any findings at that first moment.

The subjects covered in the interview were conducted in a semi-structured manner, so that some important topics could be addressed, but always giving due attention to the areas covered by the interviewee. The understanding of the activities and difficulties present in the process was also another relevant aspect taken into account in the interviews.

Contributions and responses appeared continuously and spontaneously, and the interviews lasted an average of one hour. It is worth mentioning that in the interview process, the relationships were carried out without the negative pole of the constructs to avoid confusion in the sequencing of causality and to let the interviewee's ideas flow. The negative poles were carried out by the facilitator, who knows the process, and when there were doubts, they were obtained by questioning the constructs, to understand the meaning of what the interviewee would like to say, thus eliminating possible ambiguities.

Subsequently, the problem maps were placed in the Decision explorer software, listing all constructs related to each interview and establishing the cause and effect and interdependence relationships. To finalize the process of individual maps, the constructs were grouped in Clusters and the logical consistency of the maps was verified. Thus, the maps were presented to representatives of the multidisciplinary team so that they could review the points discussed in the interview and verify the logical sequence between the constructs. Some adjustments were necessary, being made at the same time by the facilitator.

To preserve the identity of those involved and the company, the individual maps were not presented in this work. For papers purpose will be presented just the congregated map, the FIGURE 7 will be showed just in original language of interviews for maintain originality, but all causes identified from congregated map are described into section 3.2.5.

3.2.4.2. Step 4.2: Construction of the Aggregated and Congregated Map

The individual maps, already validated with their respective interviewee, were unified into a single map with the identification of Clusters. After this unification, 3 Clusters were identified: standardization (black), process (green) and performance (purple).